Bead wire

Bead wire

Bead wire is dry drawn high carbon wire with bronze coating. We produce normal tensile bead wire (NT) and high tensile bead wire (HT). Diameter range is from 0,89 mm up to 2,5 mm.

Example of our bead wire parameters

|

Diameter [mm] |

Tensile class |

Min. Braking load [N] |

Min. Tensile [N/mm2] |

Min. Total Elongation [%] |

Mass of bronze coating [g/kg] |

Number of torsions* [-] |

|

0,89 |

NT |

1200 |

1930 |

6 |

0,30 – 0,70 |

50 |

|

0,89 |

HT |

1350 |

2170 |

6 |

0,30 – 0,70 |

30 |

|

0,965 |

NT |

1375 |

1880 |

6 |

0,30 – 0,65 |

52 |

|

0,965 |

HT |

1525 |

2090 |

6 |

0,30 – 0,65 |

30 |

|

1,27 |

NT |

2360 |

1870 |

6 |

0,20 – 0,60 |

27 |

|

1,27 |

HT |

2800 |

2210 |

6 |

0,20 – 0,60 |

25 |

|

1,60 |

NT |

3800 |

1890 |

6 |

0,15 – 0,45 |

27 |

|

1,60 |

HT |

4180 |

2080 |

6 |

0,15 – 0,45 |

26 |

|

1,83 |

NT |

4750 |

1805 |

6 |

0,15 – 0,45 |

22 |

|

1,83 |

HT |

5540 |

2100 |

6 |

0,15 – 0,45 |

20 |

|

2,00 |

NT |

5250 |

1670 |

6 |

0,10 – 0,30 |

22 |

|

2,00 |

HT |

6100 |

1942 |

6 |

0,10 – 0,30 |

20 |

*testing length of sample with diameter <1,0 mm => L = 200xd; with diameter >1,0 mm => L = 100xd

Bead wire parameters can be adjusted based on customer needs.

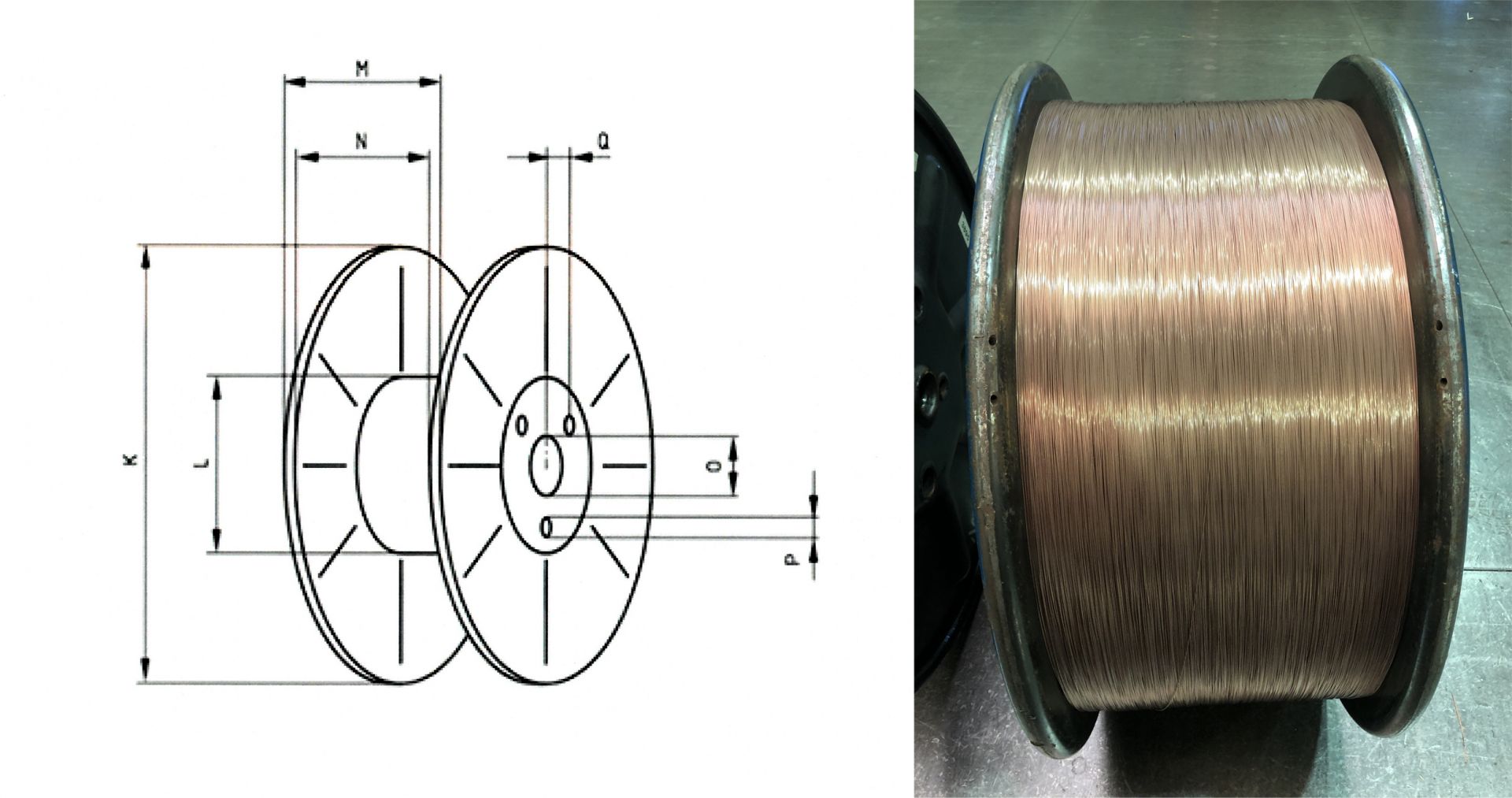

Packaging – returnable spools

Bead wire is standardly delivered on spool BS900 or BS1150 in metallic racks.

Spool dimensions are in following table.

|

|

|

BS 900 |

BS 1150 |

|

K – Spool diameter |

mm |

760 |

760 |

|

L – Core diameter |

mm |

355 |

355 |

|

M – Spool width |

mm |

330 |

370 |

|

N – Winding width |

mm |

280 |

320 |

|

O – Core hole diameter |

mm |

35 |

70,5 |

|

P – Number/diameter of drive holes |

mm |

2/35 + 2/20,5 |

2/35 + 2/20,5 |

|

Q – distance of drive hole from the middle |

mm |

115 + 63,5 |

115 + 63,5 |

Wire on spool is protected by PE foil or anticorrosive paper or combination of both. All deliveries have certificate of analysis. We can also send test samples if required. Samples are packed in PE foil bag with humidity indicator and desiccant. We can also supply bead wire on Z2 coils. For more information please contact our commercial director.